3D Printing Arizona constructs physical objects from a digital model file by adding layer upon layer of material until the desired object is complete.

Traditional manufacturing processes are often expensive and risky. 3D printing eliminates redesign cycles and allows a faster transition to production.

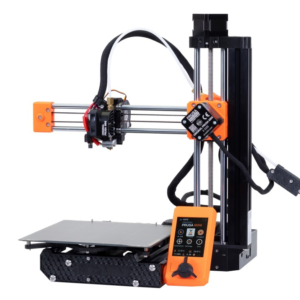

Fused Deposition Modeling (FDM) is a popular and widely available 3D printing technology that offers rapid and inexpensive production of models and functional prototypes. It uses an extruder to melt and bond semi-solid thermoplastics layer by layer, building up the structure of a part until it is complete.

FDM can produce intricate shapes with good dimensional accuracy and can be used to fabricate complex parts that would be difficult or impossible with other AM technologies. Its versatility enables it to be applied across a wide range of industries, including automotive, aerospace, manufacturing, and biomedical.

It enables users to print in multiple materials, with ABS (acrylonitrile butadiene styrene), PLA (polylactic acid) and various blends of both being the most common. Industrial-grade printers use engineering thermoplastics, such as polycarbonate and Ultem, with additives that provide specialised properties like high impact strength, thermal stability and chemical resistance.

In recent years, FDM technology has developed to the point where it has been used by doctors to create personalised prosthetics for patients. The process allows the user to select a design that closely matches the patient’s own anatomy and can be made in a fraction of the time it takes to manufacture a conventional prosthetic.

As a result, this has led to significant cost savings for patients and healthcare providers. However, the process of creating a custom-fitted prosthetic requires some specialized knowledge and training. In addition, FDM prints tend to have rough surfaces that require post-processing, such as sanding, tumbling or vapor smoothing. FDM can also have trouble printing planar features (on the XY plane) that are smaller than the nozzle diameter. This is because of the fact that filaments are deposited onto the build plate in a line, which causes layers to bond together and can cause brittleness or warping.

Stereolithography (SLA)

The original 3D printing technology, SLA works by curing liquid photopolymer resin (often called “resin”) layer by layer using a UV light source. Its high level of precision and accuracy makes it well suited for highly detailed and precise parts. This precision makes SLA printing suitable for a wide range of applications, from prototypes to medical models and beyond.

To print an object using SLA, a digital design created in CAD software is turned into a 3D file using a programming language called Standard Tessellation Language (STL). These files are used to create a stack of thin layers of liquid photopolymer resin. The UV laser then uses the light to harden each layer, building up the final object in three dimensions.

While the SLA process is ideal for producing parts with smooth surfaces, it is less effective at creating parts with complex geometry and tight tolerances. It is also susceptible to brittleness and can be prone to deformation if the printed material is exposed to sunlight or other sources of heat.

For these reasons, SLA is often best suited to prototyping or creating decorative or aesthetic elements. At Sculpteo, we use SLA printing to produce rapid aesthetic prototypes for our customers, which help them test a part’s form, fit and function without having to wait months or even weeks for a full-scale production run. It is also useful for generating tooling fixtures, which can help to avoid costly oversights during production that might otherwise cost manufacturing engineers time and money to resolve. In addition, SLA’s speed means that we can produce a prototype within a single day, which is incredibly useful when rapid iteration of designs is required.

Digital Light Processing (DLP)

DLP is a variant of stereolithography (SLA) 3D printing that uses light to cure a photosensitive polymer. During DLP printing, a digital 3D model is sliced into thin layers using specialized software, which are then printed on top of each other to form the final object. The digital model is then projected onto a vat of liquid photopolymer resin by a digital light projector, which causes the liquid to solidify in the shape of the layer being printed. This process is repeated for each layer until the entire object has been constructed.

A DLP printer’s digital light projector uses a chip that contains thousands to millions of tiny mirrors, called voxels, each representing one pixel of the digital image. As the mirrors tilt towards or away from the resin, they expose a specific voxel to UV light, which triggers the photopolymerization reaction that converts the liquid resin into a hardened layer. This meticulous manipulation of voxels allows DLP printers to produce parts with incredibly smooth surface finishes that are indistinguishable from injection-molded plastics.

Another benefit of DLP technology is that it can print very small and detailed objects that would be difficult or impossible to produce using other 3D printing technologies, such as FDM. This makes DLP ideal for rapid prototyping, allowing manufacturers to iterate on their designs and prototypes quickly and cost-effectively.

DLP printers are also popular in the medical industry, where they can be used to make prosthetics, hearing aids, and dental crowns. They can also be used to replicate models of organs and other internal bodily structures from CT scans, which helps doctors prepare for surgery and improve treatment outcomes. DLP printers are also being developed for cellular manufacturing, which could be used to create living tissues such as cartilage and bone.

Multi Jet Fusion (MJF)

MJF is a powder-based process that doesn’t use lasers, but instead uses fusing and detailing agents to melt and shape the parts. The build starts with a layer of nylon powder spread across the build plate, then droplets of fusing and detailing agents are jetted over the surface of the part to shape its geometry and provide isotropic mechanical properties (i.e., strength in all directions). The build then continues with the next layer of powder and fusing agent until the part is complete.

Compared to SLS, MJF offers faster printing times and higher accuracy in the final product. This makes it ideal for prototyping and end-use production, especially when large volumes are required. It also works with a wider range of materials than SLS, including glass-filled nylon and carbon-filled nylon.

The MJF print process can produce complex, functional prototypes and end-use parts in a wide variety of industries. For example, the automotive industry benefits from MJF printing in the design and testing of parts that can be printed quickly to accelerate time-to-market. Additionally, MJF can be used to produce complex medical devices and surgical tools that are customized to specific patients.

The consumer goods industry also relies on MJF printing to make decorative components for eyewear, footwear and elements of electronics. For instance, a swatch of leather or fabric can be produced using MJF to determine the best color for a product line before committing to a full order. Additionally, a MJF printer can easily produce complex models for the fashion industry to showcase their products. These samples can be used in stores to encourage customers to buy the products, as well as for marketing purposes.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering is a 3D printing process that utilizes specialized machines to create complex, metal parts. This technology is ideal for creating functional prototypes and end-use parts for a range of industries, including aerospace, automotive and medical. The DMLS process begins with a digital design, which is then converted into a format the machine can read. This is commonly done using CAD software, and the result is a standard tessellation language (STL) file.

Once the STL file has been input into the DMLS machine, a thin layer of metallic powder is spread across the build platform. Then, the laser scans over the surface of the powder, melting and fusing the particles in specific locations based on the Cim design. The melted and fused powder then solidifies very quickly, leaving behind a single layer of solid metal cross-section. After the laser passes, the build platform is lowered, and a blade known as a recoater applies another layer of metal powder to prepare for the next pass of the laser.

While DMLS is a relatively new manufacturing technique, it has already made a significant impact on the industry. The process allows for the creation of highly precise, complex geometries that would be impossible or cost-prohibitive to make through conventional means. In addition, DMLS provides the flexibility to print with a variety of metal alloys that can withstand high temperatures, making it suitable for use in aerospace and automotive applications.

As with other types of 3D printing, tolerances vary based on the material used and the geometry of the part. In general, DMLS parts exhibit a 2% shrinkage in the vertical direction and a 5% shrinkage in the horizontal direction.